Troubleshooting

My linear rails are crunchy, stiff, gritty, etc.

All of our rails come with a preload, higher preload bearings never feel great since the balls are rolling under load at all times. But this will be helpful to print quality.

My CB1 doesn't work and I can't get an IP

Step A: Make sure the TF card is flashed and in the right slot. Use the slot labeled SOC-CARD as there are 2 TF card slots on M8P.

Step B: Check 3.3V, 5V, 12V LED on M8P, somewhere may have a short if any leds don;t work. remove all connecters from M8P and try again.

Disco LEDs doesn't work

The disco cable connectors on each side are not same, make sure the label is right. Cable goes to DIN on the Disco. When linking/chaining the cable goes from DOUT on one to to DIN on the other.

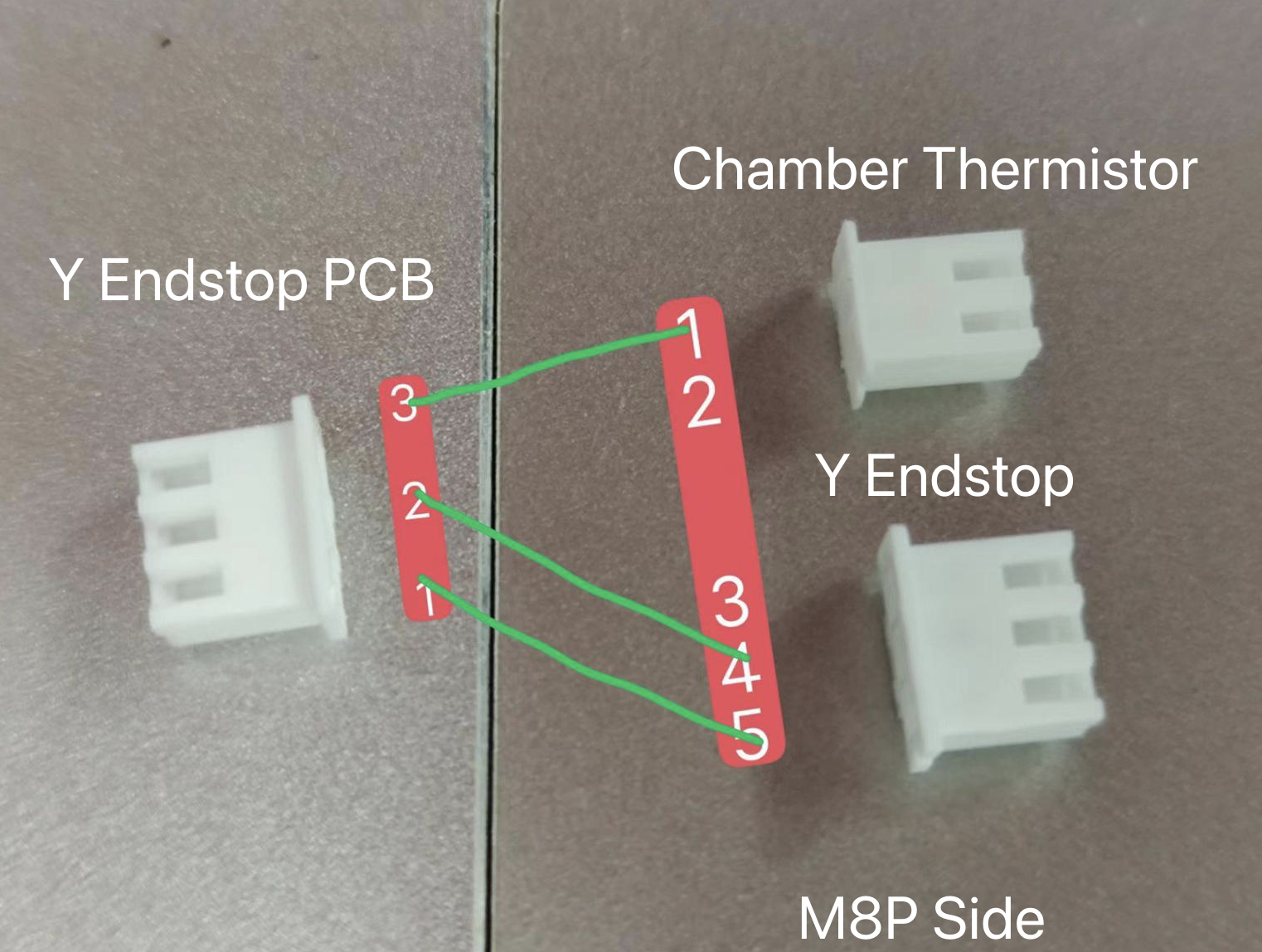

Y Endstop never triggered and/or getting wrong chamber temps

It's not your fault, it's ours.

There are wiring sequence errors in some Y endstop PCB cables.

You can use a multimeter check it. If there are errors, you can try using tweezers or a similar tool to extract the terminals and reinsert them correctly. It usually happens on 1/3 pins.

If you have any trouble with it please contact us we will send a replacement.

Tap never triggered

It is highly likely that the issue is indeed caused by wiring sequence errors. In that case, you will need to replace the terminals in a similar way as the Y endstop. You can easily exchange it on tap side (the PH2.0 connector).

If you have trouble with it, please contact us to get a replacement.

Timer too close issue and klipper shutdown

It usually happens with OrcaSlicer. First make sure the wires are fine. You can check it with a multimeter.

If wires are fine, you can try these steps:

- Set ARC G2/3 bigger, like 0.2/0.3

- Disable the dynamic fan control of OrcaSlicer.